Origins and Core Requirements of High Altitude Butane Gas Canister

Driven by User Pain Points

• Mountaineering Accident Case: 2023 frostbite incident in the Alps caused by gas canister leakage

• Standard canisters exhibit 37% flame output reduction above 2,500m altitude (data sourced from Journal of Outdoor Equipment)

Industrial Response

• 1992: Coleman pioneers "Altitude-Tuned Canister" concept

• Modern alpine canister benchmarks:

Pressure resistance ≥3.8MPa

Operational temperature -30°C to 50°C

EN417 certification compliance

High Altitude Butane Gas Canister

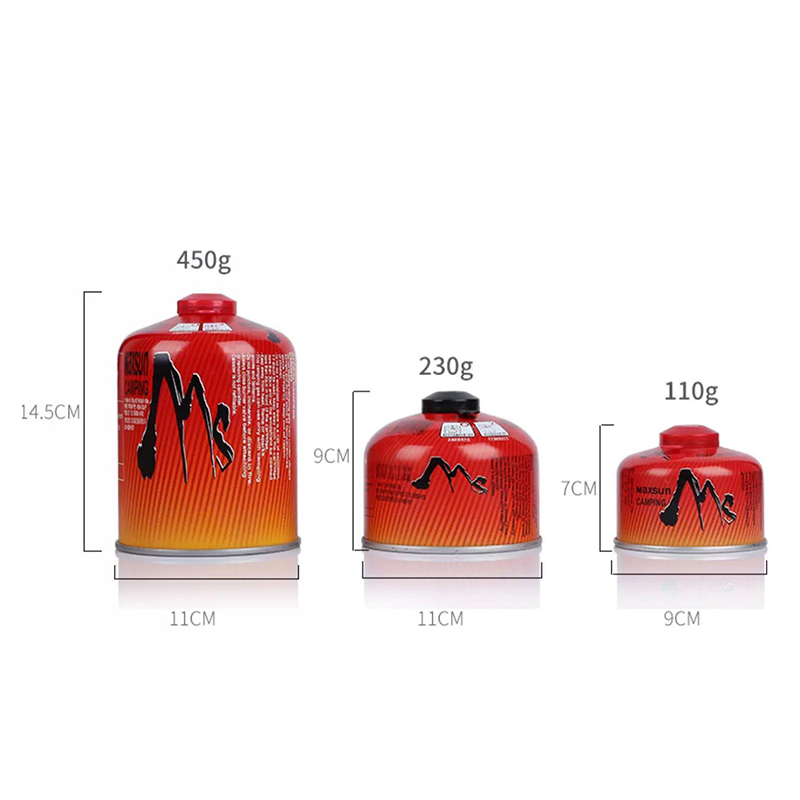

| Net Weight | Size |

| 110g | 90x70mm |

| 230g | 110x90mm |

| 450g | 110x145mm |

|

|

Feature:

√ Tank bottom high pressure buffer technology

√ Resistane to high cold & high altitude

√ International explosion-proof air outlet

√ Burn more fully & for a long time

√ High purity gas formula

Structural Differences: Two-Piece Butane Gas Canister vs. Three-Piece Butane Gas Canister

| Product Name | Two-Piece High Altitude Butane Gas Canister | Three-Piece Butane Gas Canister |

| Reference Picture |  |

|

| Can Structure | Seamless can body + base (no side welding) | Welded can body, top, and base |

| Production Process | Deep-drawn forming, better sealing | Multiple weld seams, higher leakage risk |

| Pressure Resistance | typically ≥3.8MPa | typically ≤2.5MPa |

| Cold Resistance | Works reliably at -30°C | May underperform below 0°C |

| High-Altitude Use | Optimized for 3000m+ elevation | Best for low-altitude conditions |

| Cost | Higher (premium materials & process) | Lower (mass-market production) |

Advantages of Two-Piece High Altitude Butane Gas Canister

No welds, safer: Fewer leakage points, ideal for high-pressure environments.

Better cold resistance: Seamless design avoids brittleness in low temperatures.

Why Are Two-Piece Butane Gas Canister Valves More Reliable?

Leak-proof design: Dual sealing ensures safety even if O-rings degrade.

Cold-optimized: Special valve materials prevent freezing or jamming.

Stable gas output: Maintains consistent flame in low-oxygen environments.

Why Are Two-Piece Butane Gas Canister Better for High Altitudes?

(1) Optimized Fuel Blend

Alpine canisters use isobutane + propane mix (e.g., 70/30 ratio), while standard cartridges often use pure butane.

Higher propane = better cold performance (propane boils at -42°C vs. butane at -0.5°C).

Stable vaporization at low pressure, preventing weak flame output.

(2) Higher Pressure Resistance

Alpine canisters typically have a 3.8MPa burst pressure, vs. ~2.5MPa for standard cartridges.

Withstands extreme temperature swings in alpine environments.

(3) Lightweight & Portable

Made from high-strength nickel-plated steel, alpine canisters are lighter yet stronger than standard cartridges.

Industry Standards & Buying Guide

✅ How to Identify a High-Quality Alpine Canister?

- Check certifications: EN417 (Europe), DOT (USA).

- Inspect the valve: Metal-threaded valves (plastic valves indicate lower quality).

- Weigh it: A 450g alpine canister should weigh 160-170g when empty (lighter may mean inferior materials).

🚫 Common Misconceptions

- Standard cartridges work fine for mountaineering” → May fail in cold or high-altitude conditions.

- Alpine canisters can be refilled” → Never! Non-refillable by design—extremely dangerous to tamper with.

Which One Should You Choose?

| Scenario | Recommended Choice | Reason |

| Low-altitude camping | Standard gas cartridge | Cost-effective, sufficient performance |

| High-altitude climbing | High Altitude Butane Gas Canister | Cold-resistant, high-pressure stable flame |

| Extreme conditions | High Altitude Butane Gas Canister (high propane %) | Ensures operation below -30°C |